REMBE® Explosion Safety

Hazard oriented. Risk appropriate. Reliable. Sustainable. Authentic. Safe.

When a combustible material, an ignition source and atmospheric oxygen collide in a confined space, the result is an explosion. Preventative explosion safety measures aim to stop this potentially lethal mixture from occurring. However, in practice, the vast number of potential ignition sources alone almost always makes this impossible. Consequently, the most important steps towards explosion safety for industrial companies are protection measures that minimise the damage caused by an explosion. Industrial plants must always be protected against the consequences of explosions to ensure that employees are safe and production can be resumed quickly. After all, every hour of lost production costs money. In most cases, explosion safety can be provided cost-effectively through explosion venting and explosion suppression.

We will be pleased to show you solutions tailored to your processes that will reduce the damage caused by an explosion to a negligible level – enabling you to resume production quickly after an explosion.

All REMBE® explosion vents are Made in Germany and certified in accordance with directive 2014/34/EU (ATEX) and EN 14797.

Deflagration Venting with Explosion Vents

The right explosion vent for all applications + operating conditions.

In the case of a deflagration, an explosion vent will rupture and thus protect the vessel by reducing the overpressure within it and releasing the explosion into the surrounding environment in a controlled manner. Industrial processes vary widely depending on the sector and the product. No two processes are identical. For this reason, REMBE® supplies explosion vents in a variety of different shapes, materials, temperature and pressure resistances and many other specifications. We can supply you the optimum explosion vent for your requirements. You will receive a complete protection concept that is perfectly adapted to your process.

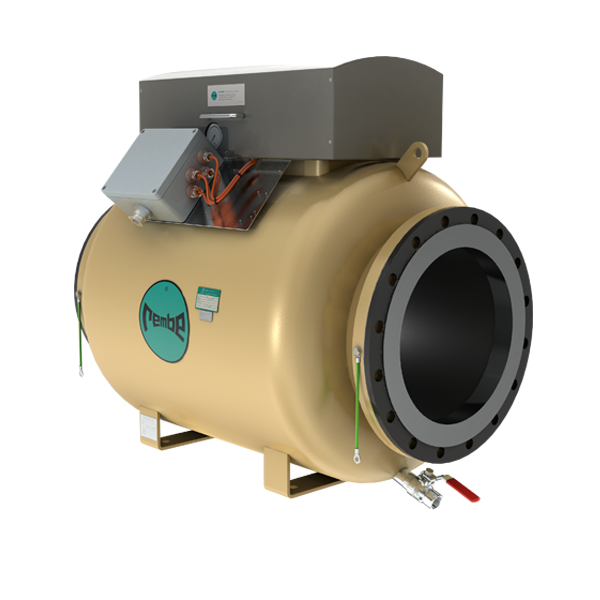

Explosion Isolation

Comprehensive protection for your plant.

Explosion isolation systems use components such as quench valves and explosion isolation flap valve. Chemical extinguishing barriers are also commonly used to smother the explosion flames. Valves and extinguishing barriers are capable of isolating components in both directions simultaneously. The objective of explosion isolation or decoupling is to protect adjacent parts of the plant and prevent the explosion from propagating. Explosion isolation is mandatory – secondary explosions in interconnected vessels would cause a high risk. Active systems have detectors or sensors which register the pressure rise or flames and trigger countermeasures, e.g. closing a valve.

Explosion Suppression

Nips the explosion in the bud.

Explosion suppression is an explosion protection measure in which the combustion of an explosive atmosphere in a closed or essentially closed volume is detected (recognised) and stopped in the initial phase, thus preventing destructive pressure increases. A controller initiates the sudden release of extinguishing powder from the extinguishing bootle into the volume to be protected in the shortest possible time. An explosion is considered suppressed if the explosion pressure does not exceed the engineered strength of the affected volume, or the degree of flame propagation remains within the specified limits in open spaces.

Flameless Venting

Deliberately not on fire.

As early as 1988, REMBE® developed the first flameless explosion venting system. It was based on a process in which the flames are cooled extremely efficiently in the mesh filter of the flame absorber and extinguished immediately. The typical pressure waves and noise pollution in the production hall that occur during an explosion are reduced to a harmless level. This guarantees maximum protection for employees and, in addition, allows the production plant to be set up in a process-optimised manner. Flameless indoor explosion venting consigns expensive protection systems with complicated vent ducts to the history books.

Explosion Prevention

Warns you before things get heat up.

Technical aids are needed to detect ignition sources at an early stage or even eliminate them completely. Similar to the 'driver assistance systems' in cars, these systems help to prevent accidents. Hidden dangers such as electrostatic charges, smouldering nests, smouldering and incipient fires can be very treacherous. Intelligent systems for grounding, temperature and gas monitoring can be used to detect and eliminate such hazards.

Accessories

Accessories for your bursting discs.

In the event of an explosion, signaling enables the system to be shut down quickly and decoupling systems to be triggered to protect adjacent parts of the system. Automated processes also use intelligent signaling systems in order to be constantly informed about the status of the entire system and any faults. This is not only mandatory in vent ducts, but can also play an important role in free reliefs. Already installed bursting discs can be retrofitted with signaling. To evaluate the signals, we offer you an isolating switching amplifier with a relay output, which ensures an intrinsically safe quiescent circuit. The potential-free relay contact is used for safe system shutdown or alarming.

Software

Calculations according to EN + NFPA.

With VENT.iNG., a software is available which supports the explosion protection expert to apply the two most common explosion VENT.iNG. approaches in the world, following EN and NFPA.

BESS Explosion Safety Series

Optimised protection of next-generation BESS systems.

Battery energy storage systems (BESS) are changing our energy landscape - and REMBE® is setting new standards in the protection of these systems. No two BESSs are the same, and each requires its own customised approach. Our integrated approach utilises multiple layers of safety, combining early detection and flammable concentration reduction options with optimised deflagration ports to protect next-generation BESS assets. REMBE® offers a comprehensive range of products to protect BESS from explosions. Different product series enable optimal solutions for each BESS installation, each bringing unique benefits to your project.

Any Questions?

We would be happy to show you solutions tailored to your process that limit the effects of an explosion to a harmless level and ensure that production can be resumed quickly after an explosion event.